Prodotti

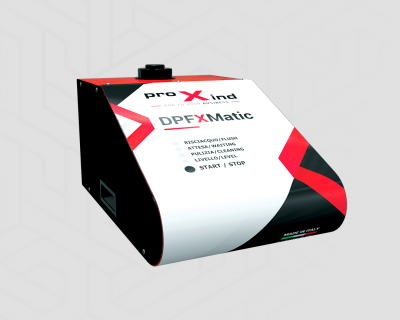

Machine for cleaning the intake manifold in gasoline and diesel vehicles

CleantakeX by Proxind is a one-of-a-kind intake manifold cleaning machine specifically designed for additive manufacturers.

Proxind’s innovation lies in the use of a portable device for this function, instead of using spray cans, to improve its performance.

The cleaning of the intake manifold is carried out by the machine using additives, in a automatic way, and with no need to remove any part of the vehiclen thus avoiding considerable time waste.

Advantages

CUSTOMIZATION

Private Label

Customization

Graphic customization of the control panel with company logo

Customized design of the structure, both in shape and in corporate colors

Software with customized programming according to customer specifications

Possibility to show the brand and the commercial name of the liquids used

Your brand and your liquids will always be clearly visible

QUALITY MADE IN ITALY COMPONENT

CleantakeX by Proxind is produced in Italy with Italian top quality components that guarantee a great durability in time.

EASY TO USE

One-man

operation

Intuitive

and fully customizable

On-display menu selectable with a simple rotary selector switch and push button

Maintenance

To avoid more serious potential problems, a preventive service to clean the injectors in diesel and gasoline engines is recommended, eliminating carbon deposits and combustion residues.

CleantakeX by Proxind allows this treatment, with no need to remove any part of the engine, avoiding, in this way, a considerable waste of time and money.

INJECTION SYSTEM CLEANING - INJECT TREATMENT

With this treatment, CleantakeX cleans the intake manifold by spraying specific additives into the air intake of the vehicle, removing carbon and oil deposits and restoring the correct functioning of the engine.

It is the only machine that sprays the cleaning additive in the air intake system through a pump. In the other machines available on the market, instead, the cleaning additive is sprayed by the vehicle itself as a result of the Venturi effect. The duration of the spray and the break time between one spray and the next one can be set on the display menu; furthermore, an electronic system prevents the draining of the product at the end of any spray into the intake duct.

Technical Specifications

| SPECIFICATIONS | TECHNICAL DATA |

| Dimensions of standard model | 225 x 240 x 370 mm (W x H x D) |

| Weight of standard model | 7 Kg |

| Multilingual Software | • Languages present in the software: Italian, English, German, French, Spanish, Portuguese and Turkish • Possibility to add new languages in the software on request |

| Power supply | 12 Vdc – from vehicle battery socket using a special power cord |

| Electronic board with microcontroller | • Electronic system to indirectly detect low levels of the tank • Electronic control of the pressure |

| Pump | Electronically controlled magnetic drive steel gear pump |

| Tank | 1 l |

| Service pipes | N.1 pipe with quick-connect fittings |

| Display | Monochromatic alphanumeric, 4 rows x 20 characters |

Italian

Italian English

English French

French German

German Portuguese

Portuguese Russian

Russian Spanish

Spanish Turkish

Turkish