Prodotti

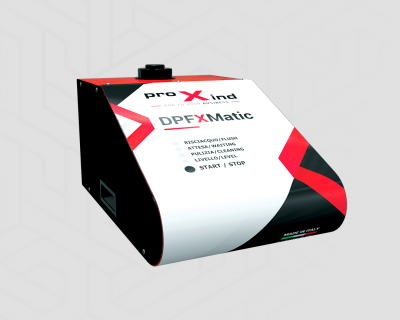

Machine for flushing the automatic transmission, changing the ATF oil and adding the permanent additive

ATFXMatic by Proxind is an automatic transmission flushing and ATF oil change machine, specifically designed for manufacturers of ATF oils for automatic vehicle transmissions.

With ATFXMatic ATF oil can be changed and the transmission cleaned with a fully automatic device and with no need to remove any part of the vehicle, thus avoiding considerable time waste.

Increasingly advanced automatic transmissions require more and more specialized maintenance, and the growing competitiveness in the automotive fluids sector requires solutions to stand out through automatic and more professional devices.

Advantages

CUSTOMIZATION

Private Label

Customization

Graphic customization of the control panel with company logo

Customized design of the structure, both in shape and in corporate colors

Software with customized programming according to customer specifications

Possibility to show the brand and the commercial name of the additive and oil used

Your brand and your liquids will always be clearly visible

QUALITY OF THE MADE IN ITALY COMPONENTS

ATFXMatic by Proxind is produced in Italy with Italian top quality components that guarantee a great durability in time.

EASY TO USE

Use through a single operator

User-friendly and completely automatic

Automatic detection of the flux direction

Menu on the display selectable

with only 4 buttons: ESC, OK, ↓, ↑

DATABASE IN ONE CLICK

ATFXMatic has an online, constantly updated and fast to consult database, unlike databases integrated in the machine.

Through the database, the suitable fitting can be found in one click, searching by vehicle model.

Through pictures and texts, it provides the following informations:

> Automatic transmission lubricants (type recommended by the parent company and amount)

> Procedures for ATF oil change of automatic transmission

> Procedures for ATF oil level control of automatic transmission

> Pictures of the attachment points for the fittings used to substitute the ATF oil

> Pictures and description of the fitting types used to substitute the ATF oil

Technical Specifications

| SPECIFICATIONS | TECHNICAL DATA |

| Dimensions of standard model | 650 x 1130 x 450 mm (W x H x D) |

| Weight of standard model | 61 Kg |

| Fittings | • Standard fitting set • Optional fitting set |

| Multilingual Software | • Languages present in the software: Italian, English, German, French, Spanish, Portuguese, Russian, Romanian, Serbian, Polish, Turkish, Dutch and Suomi • Possibility to integrate new languages in the software on request |

| Power Supply | • 12 Vdc – from the vehicle battery using a special power cord • Electronic device of protection for the inversion of the poles of the battery during connection • 110-230 VAC through an optional internal switching convertor AC/DC |

| Electronic board with microcontroller | • System based on the weighing of new and used oil with load cells, which allows you to replace exactly the same amount of oil, regardless of the difference in temperature, and therefore volume, between the new and used oil • It checks the speed of the pump and so its capacity according to/in function of the waste oil eliminated every second, with the PWM (Pulse Width Modulation) technique • It oversees the process with all the necessary precautions. For example, it does not allow the oil change operation if the new oil tank does not contain enough oil, or if the used oil tank is not capable of receiving the replaced oil |

| Pump | Gear pump for oil, with direct current engine 12Vdc |

| Filter | Filter 10 micron in the round trip circuit able to bear high pressures, up to 12 bar |

| Detection of the direction of the flux | • Automatic • The service pipes can be inserted in the most functional point of access no matter the direction of the flux |

| Tanks | • Technical capacity of the new and waste ATF oil: 25 litres • Easy to remove and available on the market |

| Additive Tank | • Wash and permanent additive tank capacity: 3 liters • Additive tank has a minimum level sensor |

| Service Pipes | Delivery and return tubes are 250 cm long with rapid attack such as Nitto (Japan profile) at the end |

| Printer | • Thermal with 24 columns • Located on the control panel, it allows you to print the relevant data of the process, such as the quantity, name of the oil changed, etc. |

| Display | Monochromatic alphanumeric 4 rows x 20 characters |

| Electronic sensor of the temperature | Placed on the oil return circuit, it automatically switches from the/recirculation and cleaning phase to the replacement phase when it detects that the oil has reached a temperature of 40° |

| Recirculation circuit | • If the oil, at the end of the cleaning phase, hasn’t reached the necessary temperature of 40°, the recirculation phase remains active until it reaches this temperature • It protects the automatic transmission in case of malfunction, keeping ATFXMatic automatically in the recirculation phase |

| Acoustic and light signals | Provided whenever warning the operator is needed, for example when malfunctioning occurs |

Italian

Italian English

English French

French German

German Portuguese

Portuguese Russian

Russian Spanish

Spanish Turkish

Turkish