Prodotti

Machine for washing the heat exchanger of boats

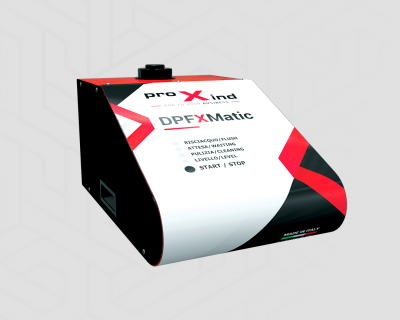

OceanXMatic by Proxind is a machine for washing the marine heat exchanger, designed specifically for companies producing specific detergents and descaling liquids for boat radiators.

In fact, the circulation of sea water in the heat exchanger can cause fouling due to the sediments of salt and limescale.

These sediments, generated by the high heat exchange, tend over time to clog the ducts, reducing the cooling capacity and promoting internal corrosion.

In this case, disassembling the heat exchanger and taking it to a nautical workshop, where it is descaled and cleaned by immersing it in special cleaning tanks, is necessary.

With OceanXMatic regular cleaning treatments of the heat exchanger can be carried out in order to avoid possible incrustations that may emerge, which may lead to engine overheating and consequent need to have it repaired at a specialized shop, with considerable money expenditure.

Advantages

Customization

Private Label

Customization

Graphic customization of the control panel with company logo

Customized design of the structure, both in shape and in corporate colors

Software with customized programming according to customer specifications

Your brand will always be

clearly visible

Quality of components Made in Italy

OceanXMatic by Proxind is produced in Italy with top quality Italian components, which guarantee great reliability over time.

EASY TO USE

One-man

operation

Intuitive

and fully customizable

Menu on 4-digit numeric display with 7 segments selectable with only 4 buttons: START, STOP/MODE, ↓, ↑

Technical Specifications

| SPECIFICATIONS | TECHNICAL DATA |

| Dimensions of standard model | 530 x 490 x 510 mm (W x H x D) |

| Weight of standard model | 30 Kg |

| Adapters | The machine is equipped with three pairs of adapters (25/32 mm, 38/50 mm and 60/70 mm) to connect the machine to the heat exchanger |

| Power supply | 12 Vdc – from the battery socket of the boat using a special power cord |

| Pump | • Immersion pump • Max flow rate = 1363 liters/h |

| Filter | • Filter on return pipe • Rope filter cartridge 7 inches, 50 microns |

| Tank | • Tank capacity: 33 liters • Min level sensor • Max level sensor |

| Service Pipes | • Delivery and return hoses are approximately 4 m long with quick-connect fittings on the ends • The discharge pipe is 4 m long |

| Display | 4-digit, 7-segment numeric display for setting the treatment time from 0 to 99 min, advancing 10 seconds at a time |

| Solenoid valves | N.2 two-way solenoid valves with EPDM membrane |

Italian

Italian English

English French

French German

German Portuguese

Portuguese Russian

Russian Spanish

Spanish Turkish

Turkish